A Cornerstone of Digital Manufacturing

A Cornerstone of Digital Manufacturing

In the ever-evolving landscape of manufacturing, digitalization has become the cornerstone of innovation and efficiency. As we delve into the era of Industry 4.0, digital manufacturing has emerged as a transformative force that reshapes how products are conceived, designed, produced, and maintained. This paradigm shift not only enhances productivity but also opens up new opportunities for businesses to thrive in a highly competitive global market.

What is Digital Manufacturing?

Digital manufacturing, in its essence, is the integration of digital technologies into every phase of the manufacturing process. It leverages a range of cutting-edge tools and concepts such as the Internet of Things (IoT), Artificial Intelligence (AI), data analytics, and 3D printing to streamline operations and make them smarter. These technologies work in unison to optimize production, reduce costs, and improve product quality.

The Four Pillars of Digital Manufacturing

- Data-Driven Decision-Making: In digital manufacturing, data is king. Sensors and IoT devices collect real-time data from machines, products, and the environment. This wealth of information enables manufacturers to make informed decisions promptly. For instance, predictive maintenance uses data analytics to predict when equipment is likely to fail, allowing for proactive maintenance, minimizing downtime, and reducing costs.

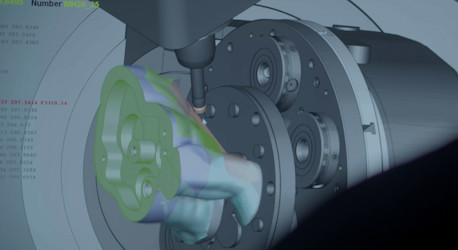

- Smart Automation: Automation has been a game-changer in manufacturing, but with digitalization, it becomes even smarter. Robots and machines can now communicate with each other and adapt to changing conditions. This level of automation improves efficiency and allows for more flexible production processes.

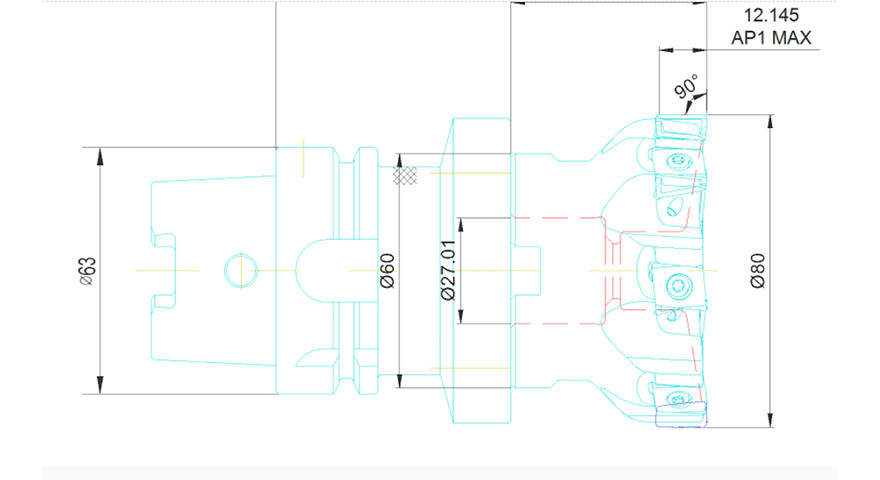

- Digital Twin Technology: Digital twins are virtual replicas of physical products or processes. They enable manufacturers to simulate and test different scenarios before actual production. This reduces the risk of errors and accelerates innovation. For instance, in the aerospace industry, digital twins are used to design and test aircraft components without physically building them, saving time and resources.

- Supply Chain Optimization: Digital manufacturing extends beyond the factory floor. It encompasses the entire supply chain. Manufacturers can track the movement of raw materials, components, and finished products in real-time. This transparency helps in optimizing logistics, reducing lead times, and minimizing waste.

Benefits of Digital Manufacturing

The adoption of digital manufacturing brings a multitude of benefits to businesses:

- Cost Efficiency: Reduced operational costs through predictive maintenance, waste reduction, and improved resource allocation.

- Quality Improvement: Enhanced product quality and consistency through real-time monitoring and control.

- Flexibility: Greater adaptability to changing market demands and customization of products.

- Speed to Market: Faster development and production cycles, allowing companies to bring products to market more quickly.

- Competitive Advantage: A strategic edge in the global market by embracing the latest technologies and staying ahead of the competition.

- Sustainability: Reduced environmental impact through optimized resource utilization and waste reduction.

Conclusion

Digital manufacturing is not merely a buzzword; it’s a fundamental shift in how manufacturing operates. It empowers businesses to become more agile, cost-effective, and environmentally responsible. Embracing digital manufacturing is not just a choice but a necessity in today’s fast-paced and competitive industrial landscape. As we move forward, those who harness the power of digitalization will stand as the true innovators and leaders in the world of manufacturing.