Closing the loop in digital manufacturing

Closing the Loop in Digital Manufacturing

In the ever-evolving landscape of manufacturing, the concept of “closing the loop” has gained significant prominence. It’s not just a buzzword; it’s a fundamental transformation that is shaping the future of digital manufacturing. But what exactly does “closing the loop” mean in this context, and why is it so crucial? Let’s delve into this exciting development and understand its implications.

Understanding the Loop

To comprehend the concept of closing the loop, we must first grasp the basic manufacturing process. Traditional manufacturing involves several stages, including design, production, quality control, and distribution. Each of these stages operates somewhat independently, with limited communication and interaction.

Closing the loop, however, envisions a seamless integration of these stages. It’s about creating a continuous feedback system that connects all aspects of manufacturing, from initial design to final product delivery. This loop ensures that information flows freely between stages, enabling real-time adjustments and improvements.

The Digital Revolution

The advent of digital technologies has been a catalyst for closing the loop in manufacturing. Here’s how it’s happening:

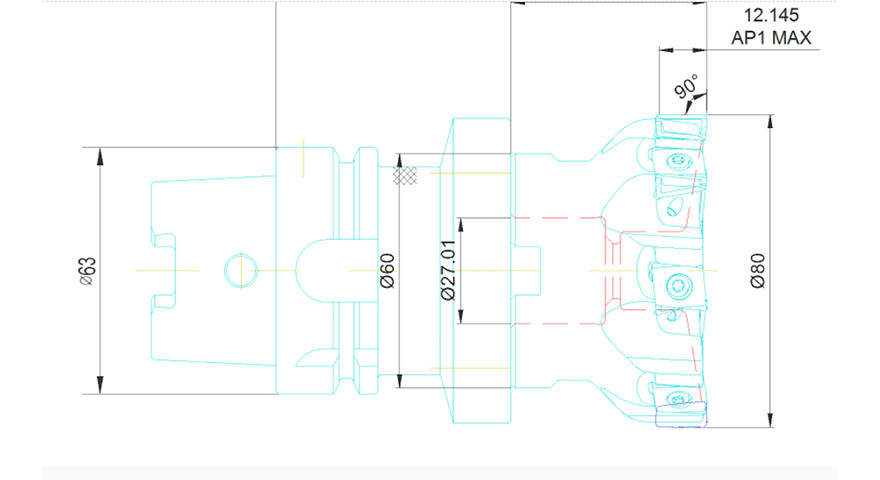

Design and Simulation

In the digital age, products are not just designed on paper; they are simulated in a virtual environment. Engineers can test various designs, materials, and production processes before any physical prototypes are created. This digital design phase lays the foundation for a more efficient and error-free manufacturing process.

IoT and Sensors

The Internet of Things (IoT) has enabled manufacturers to embed sensors in machines and products. These sensors collect data in real time, providing insights into the performance and health of equipment. This data is invaluable for predictive maintenance, reducing downtime, and optimizing production.

Big Data and Analytics

The data generated by IoT devices, along with other relevant data sources, is processed through advanced analytics. Machine learning algorithms can identify patterns, anomalies, and potential issues in manufacturing processes. This proactive approach allows for quick interventions and quality control.

Supply Chain Integration

Closing the loop extends beyond the factory floor. It involves integrating the entire supply chain. Manufacturers can track the movement of raw materials, components, and finished products in real time. This visibility improves inventory management, reduces bottlenecks, and enhances overall efficiency.

Benefits of Closing the Loop

The advantages of closing the loop in digital manufacturing are multifold:

Cost Reduction

By identifying and addressing issues early in the process, manufacturers can save on repair and maintenance costs. Predictive maintenance alone can lead to substantial savings.

Improved Quality

Real-time monitoring and data analysis lead to higher product quality. Fewer defects mean fewer recalls and warranty claims, saving both money and reputation.

Enhanced Efficiency

Efficiency gains result from streamlined processes, reduced downtime, and optimized resource utilization. This efficiency directly impacts the bottom line.

Customization

The flexibility offered by digital manufacturing allows for more product customization. Manufacturers can respond quickly to customer demands, increasing market competitiveness.

Sustainability

Closing the loop promotes sustainability by minimizing waste and energy consumption. Efficient processes and reduced defects contribute to a greener manufacturing ecosystem.

Closing Thoughts

In conclusion, closing the loop in digital manufacturing represents a significant leap forward in the world of production. It leverages the power of digital technologies to create a tightly integrated, feedback-driven manufacturing ecosystem. Manufacturers that embrace this concept are not only poised for higher efficiency and profitability but are also contributing to a more sustainable future.

As we move further into the digital age, the importance of closing the loop will only grow. It’s not just a trend; it’s the future of manufacturing. Embracing it today will ensure that your manufacturing business remains competitive, agile, and ready for the challenges and opportunities of tomorrow.